Static Var Compensator (SVC) is built on proven thyristor technology. The state-of-the-art thyristor valve is extremely compact in design and delivers superior performance compared with other solutions available in the market.

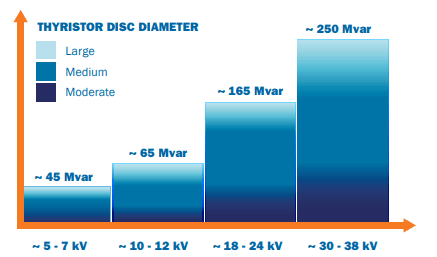

Fast reactive power compensation with SVC ensures effective flicker mitigation and voltage variation control in steel plants with electric arc furnaces (EAFs), in mining plants with mine winders, excavators, crushers and grinders or to enhance transmission capacity and achieve unity power factor in utilities. SVC provides tailored solutions to meet customer requirements from 3.3KV up to 38.5kV 250MVAr. Merus Power can deliver a complete turnkey solutions.

Voltage can be controlled by controlling the

reactive power flowing in the system. The reactive power can be consumed with inductive

reactance (reactors) and produced with capacitive reactance (capacitors). SVC can be

understood as adjustable impedance that provides reactive power proportionally to the system

supply voltage. SVC impedance can be modified by combining adequate amounts of inductive and

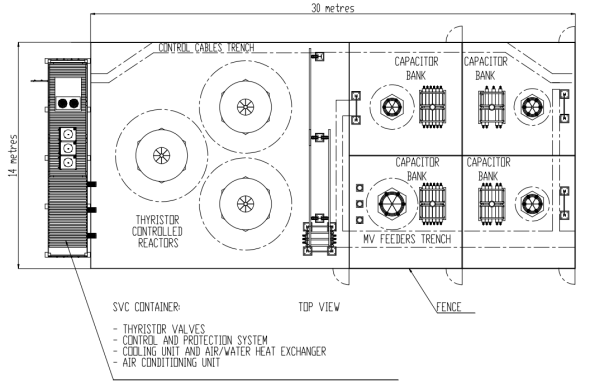

capacitive reactance. Inductance is provided by thyristor controlled reactors (TCR) using

Merus thyristor valves, while the capacitive part consists of fixed capacitor banks.

When the inductive part is operating at maximum current, the SVC’s output reactive power

is zero or inductive, drawing the voltage of the connection point down. When inductive part

current is zero, the SVC system, with its maximum capacitive power, pulls the voltage of the

connection point up. The capacitor banks also work as passive harmonic filters, fine-tuned

to reduce harmonics generated by the thyristors of TCR and by the loads. With the

line-commutated thyristors the reaction time of SVC is typically half a network cycle.

Main benefits of SVCs can be summarized as:

1. Increased productivity of

steel plants by reducing melt-time

2. Increased torque and payload of large inductive loads with stabilized voltage

3. Transmission and distribution network capacity enhancement

4. Longer plant lifetime

5. Reduced maintenance costs

6. Improved plant reliability

Typical Applications

SVCs have many low and high voltage potential applications where their use offers many benefits.

⦿ Installations with fast changing reactive power demand

like electric arc furnaces and ball mills.

⦿ Highly

dynamic loads where the power factor fluctuates rapidly or in big steps like cranes, sawmill

machinery, welding machines, etc.

⦿ Correction of

leading power factor like in data centers allowing back-up generators

operation.

⦿ UPC systems.

⦿ Solar inverters and

wind turbine generators.

⦿ Railway electrification systems: Trains &

trams

⦿ Loads with low power factor: Motors,

cables, lightly loaded transformers, lighting, etc.